Different countries have different requirements on it in the United States , are ” generally recognized as safe ” food additives , flour maximum use level is 45ppm; in the UK, it is considered to cause respiratory sensitive , that its presence in the workplace may induced asthma ; in China , but also as a flour treatment agent limited use . World Health Organization believes that the limited animal experiments show that azodicarbonamide after being inhaled or ingested animal , most are not absorbed and rapidly through the feces is discharged , low acute toxicity in experimental animals , not on skin , eye and respiratory tract irritation. There is not enough research to prove azodicarbonamide on animal or human carcinogens or reproductive toxicity. But there is ample evidence that azodicarbonamide can induce asthma and other respiratory symptoms occur , may also make the skin sensitive to workers exposed to azodicarbonamide in their harmful to other systems are no studies .

However, this chemical is easier accused in three aspects affect human : including the destruction of flour vitamins, calcium absorption and impact damage to the body’s vital organs and induce cancer. Therefore , the United Kingdom , the European Union , Australia, New Zealand, Singapore and Japan have banned the use of azodicarbonamide in food .

Category Archives: Organic chemicals

Use of hydrogen peroxide

The use of hydrogen peroxide for medical , military and industrial use are three daily disinfection of the medical hydrogen peroxide, hydrogen peroxide can kill intestinal bacteria of medical , pyogenic bacteria, pathogenic yeasts , generally used for surface disinfection . Oxidation with hydrogen peroxide , but the medical hydrogen peroxide concentration equal to or less than 3% , wiping the wound surface , there will be a burning sensation , the surface is oxidized to white and fizzy , wash with water can, over 3-5 minutes restore the original color .

Chemical industry for the production of sodium perborate , sodium percarbonate, peracetic acid , sodium chlorite, sulfur dioxide and other materials urea , tartaric acid , vitamins and other oxidants. The pharmaceutical industry as a bactericide , disinfectant, and the production of pesticides and 40l thiram antimicrobial oxidants . Cotton fabric dyeing industry as a bleaching agent , restore hair color after dyeing agent . For removing iron and other heavy metal salts , or the production of other compounds . Also used in electroplating solution, inorganic impurities can be removed to improve plating quality. Also used wool, silk , fur , feathers, ivory , bristles , pulp , fat bleaching . High concentrations of hydrogen peroxide can be used as rocket fuel power .

Civil : Handle Kitchen sewer smell,

To the pharmacy to buy hydrogen peroxide plus water plus detergent down the drain , can decontamination, disinfection, sterilization ;

3% hydrogen peroxide ( medical grade ) available wound disinfectant ;

[ 5 ] In the laboratory preparation of hydrogen peroxide can be used for production of oxygen , fast and convenient , but the high cost , the preparation should not be used in industrial or large scale preparation .

Oxalic acid and chemical properties

Oxalic acid at 100 ℃ start sublimation , when rapid sublimation 125 ℃ , 157 ℃ when a large number of sublimation , and begin to decompose.

With a base , may occur esterification, acid halide , an amidation reaction . Reduction reaction can also occur , heat decarboxylation reaction . Anhydrous oxalic acid is hygroscopic . Oxalic acid can dissolve in water to form complexes with many metals .

Acidity

Oxalic acid than acetic acid ( acetic acid ) 10000- X , the acid is an organic acid . Its an ionization constant Ka1 = 5.9 × 10 ^ -2, two ionization constant Ka2 = 6.4 × 10 ^ -5. With continuity acids. Can occur with alkali neutralization, the indicator can change color , can emit carbon dioxide and carbonate role .

For example : H2C2O4 + Na2CO3 == Na2C2O4 + CO2 ↑ + H2O

H2C2O4 + Zn == ZnC2O4 + H2 ↑

Reductive

Oxalate has a strong reduction, and oxidant easily oxidized into carbon dioxide and water [ 1 ] . Can make acidic potassium permanganate (KMnO4) solution fade, and reduced to divalent manganese ions. This reaction is used as a quantitative analysis method for determining the concentration of potassium permanganate . Oxalic acid can also wash away spilled ink on the cloth track .

2KMnO4 +5 H2C2O4 +3 H2SO4 == K2SO4 +2 MnSO4 +10 CO2 ↑ +8 H2O

H2C2O4 + NaClO == NaCl +2 CO2 ↑ + H2O

Instability

Oxalic acid at 189.5 ℃ or in case of concentrated sulfuric acid will decompose to produce carbon dioxide , carbon monoxide and water.

H2C2O4 ==== CO2 ↑ + CO ↑ + H2O

Laboratories can use this reaction to the admission of carbon monoxide gas .

Hydrogen oxalate to carbon dioxide, carbon monoxide, ammonia , and water 200 degrees

Toxicity

Oxalic acid is poisonous. On the skin , mucous membrane irritation and corrosion, easily through the skin , mucous membranes absorb lead poisoning . Air maximum allowable concentration of 1m g/m3.

Esterification

Acetic acid ester with an alcohol can be generated . For example, the reaction of acetic acid with ethanol, ethylene malonate.

Chemical and physical properties of formic acid

Flammable. With water , ethanol , ether and glycerol arbitrary miscible with most polar organic solvents , in hydrocarbons also have some solubility.

Relative density (d204) 1.220. Refractive index

1.3714 . Heat of combustion 254.4 kJ / mol, the critical temperature 306.8 ℃, critical pressure 8.63 MPa. Flash point of 68.9 ℃ ( open cup ) . Density of 1.22 , 1.59 Relative vapor density (air = 1 ) , the saturated vapor pressure (24 ℃) 5.33 kPa.

High concentrations of formic acid in the winter easy to freeze.

Incompatibility: Strong oxidizers , strong alkalis, reactive metal powders.

Hazardous characteristics: its vapor and air can form explosive mixtures case of fire , high- heat combustion caused the explosion. May react with strong oxidizing agents .

Solubility: miscible with water insoluble hydrocarbons , soluble in alcohol.

And the gas in hydrocarbons , the carboxylic acid to form a dimer through hydrogen bonding occurs . In gaseous hydrogen bonds lead to the existence of a large deviation between the acid gas and the ideal gas equation of state . Formic acid by the liquid and solid continuous acid through hydrogen bonding molecules .

Catalytic decomposition of formic acid in concentrated sulfuric acid to CO and H2O:

Due to the special structure of formic acid , one of its hydrogen atoms and carboxyl groups directly connected. Is a hydroxyl group can also be seen as formaldehyde. Therefore, formic acid and formaldehyde , and both properties.

Unlike most other carboxylic acid having the same properties , although not usually an acid chloride or acid anhydride. Acid dehydration decomposition of carbon monoxide and water. Carboxylic acid having reducing aldehydes like . It can play silver mirror reaction, the reduction of silver ions in the ammonia complex silver ions to metallic silver , while he is oxidized into carbon dioxide and water :

Formic acid is the only olefin addition reaction and a carboxylic acid . Carboxylic acid under the action of an acid ( such as sulfuric acid , hydrofluoric acid ) , and the rapid reaction of the olefin ester . However, a side reaction similar to the Koch reaction can also occur , is a more advanced product of a carboxylic acid .

Octanol / water partition coefficient : -0.54 , explosive limit % (V / V): 57.0, lower explosive limit % (V / V): 18.0.

Formic acid is a strong reducing agent , the silver mirror reaction can occur . Saturated fatty acids in the most acidic dissociation constant of 2.1 × 10-4. At room temperature slowly decomposed into carbon monoxide and water. And concentrated sulfuric acid heated to 60 ~ 80 ℃, decompose to release carbon monoxide . Formic acid is heated to above 160 ℃ decomposition that emit carbon dioxide and hydrogen. Alkali metal salts of formic acid was heated to 400 ℃ generated oxalate .

Molecular structure data

1 , the molar refractive index: 8.40

2 , molar volume (m / mol): 39.8

3 , parachor (90.2K): 97.5

4, the surface tension (dyne / cm): 35.8

5 , the polarization ratio (10cm): 3.33

Alkyl Polyglucoside Basic Information

Alkyl Polyglucoside, referred to APG, from renewable natural resources, synthetic fatty alcohols and glucose, a new overall performance than the nonionic surfactant, both ordinary non-ionic surfactants and anionic properties, with high surface activity , good safety and ecological compatibility, is an internationally recognized choice for “green” functional surfactant.

Alkyl Polyglucoside low surface tension, no cloud point, HLB value is adjustable, moist and strong, strong detergency, foam rich and delicate, compatibility strong, non-toxic, harmless, non-irritating to the skin, biodegradable quickly and thoroughly, can be used with any type of surfactant complex, synergistic effects are obvious. Has a strong broad-spectrum antimicrobial activity, product thickening effect is remarkable, easy-to-diluted, non-gel phenomenon, easy to use. And alkali resistant, resistant to acid, resistance to hard water, salt and strong. Can be used as shampoo, the main raw material shower gel, facial cleanser, laundry detergent, hand soap, dishwashing liquid, fruits and vegetables daily chemical cleaning agents. Also used in soap powder, phosphate-free detergents, phosphate-free detergents and other synthetic detergents. Can be used as food, pesticides, silicone emulsion dispersant; pesticides, herbicides synergist; plastic sheeting fogging agents, plastic additives; may also be used in the pharmaceutical, biotechnology, industrial cleaning, fire fighting agents, textile , paints, photographic materials, leather, oil, mineral, rubber, energy and other areas.

Alkyl Polyglucoside product safety (non-toxic byproducts dioxane), mild and antibacterial advantage, adapt to the future direction of personal care products, will replace the existing petroleum-based surfactants mainstream surfactant.

Alkyl Polyglucoside can be used for preparing the solid dispersions, plastics additives. Although the Alkyl Polyglucoside compounds are stable, but with the remaining three hydroxyl groups on the sugar further synthesis of various esters and other derivatives (such as an ether). Alkyl Polyglucoside connected as carboxylic acids may be prepared, or other various anionic APG esters such as sulfo succinate, citrate, tartrate, maleate, sulfate, phosphate and the like. The first three esters commercially available abroad, they have good foaming properties, compatibility, gentle on the skin, does not irritate the eyes, and does not contain dioxane, ethylene oxide and nitrosamines, etc., so it is applicable in cosmetics and personal protective equipment. Furthermore, Alkyl Polyglucoside also be synthesized alkoxylate quaternary ammonium salt cation and SAA,

chloramine B MSDS

English name : chloramine B

CAS NO. 127-52-6

English alias sodium N-chlorobenzenesulphonamide; Cholramine-B; N-Chlorobenzenesulfonamide sodium salt; sodium chloro (phenylsulfonyl) azanide; sodium chloro (phenylsulfonyl) azanide hydrate; [benzenesulfonyl (chloro) amino] sodium

EINECS 204-847-9

Formula : C6H5ClNaNO2S

Supplies:http://www.lubonchem.com

CAS: 127-52-6

Appearance: white crystalline powder

Content : 99% Min

Chlorine : 27% Min

Clarity : clear and transparent

PH: 9-11

Iron : 10ppm Max

Heavy metal : 10ppm Max

Packing : 25Kg/50Kg cardboard

1 , security terms

S7Keep container tightly closed.

Keep container tightly closed .

S22Do not breathe dust.

Do not breathe dust.

S26In case of contact with eyes, rinse immediately with plenty of water and seek medical advice.

In case of contact with eyes, rinse immediately with plenty of water and seek medical advice .

S36/37/39Wear suitable protective clothing, gloves and eye / face protection.

Wear suitable protective clothing , gloves and goggles or masks.

S45In case of accident or if you feel unwell, seek medical advice immediately (show the label whenever possible.)

In case of accident or feel unwell, seek medical advice immediately ( if possible show the label ) .

2 , the term risk

R2Risk of explosion by shock, friction, fire or other source of ignition.

By shock, friction , fire or other sources of ignition explosion hazard.

R31Contact with acids liberates toxic gas.

Contact with acids liberates toxic gas.

R34 Causes burns.

Cause burns.

R42May cause sensitization by inhalation.

May cause sensitization by inhalation .

Purposes: organic chlorine disinfectant containing chlorine 26-28 % of the more stable, sealed to maintain a year lost only 0.1% of available chlorine . Slightly soluble in water , irritating and corrosive smaller role than hypochlorous slowly. Mainly used for drinking utensils, various utensils , fruits and vegetables disinfection (5ppm), farming and enamelware water disinfection ( 1% ) . Can be used for milking cows and cleaning the breast and livestock invasive urinary tract and purulent washing and disinfection.

Sodium gluconate MSDS

1, the basic information

Chinese name : Sodium gluconate

Chinese alias : D- glucose , sodium

Name : Gluconic acid, sodium salt

English Name : SODIUM GLUCONATE RE; Gluconic Acid Sodium; Sodium gluconate; sodium 2,3,4,5,6-pentahydroxyhexanoate (non-preferred name)

CAS No. :527 -07-1

EINECS No. :208 -407-7

Formula : C6H11NaO7

Molecular Weight : 218.14

Melting point :206-209 ℃

Appearance: white crystalline powder or granules.

Solubility: easily soluble in water , slightly soluble in alcohol, can not soluble in ether.

Specifications : Complies with FAO standard FAO / WHO; USPXX Ⅲ version ; corporate standards ; also according to customer requirements.

Packing : 5Kg plastic woven bags ; also according to customer requirements.

Uses:

One for medicine, you can adjust the acid-base balance in the human body to restore nerve function normally , for the same purpose , used in food additives ;

Water is used as a stabilizer , and its superiority in:

⑴ obviously coordinated effects, for molybdenum, silicon, phosphorus , tungsten, nitrite , and other formulations , the coordination Effect , inhibition effect of greatly increased ;

⑵ contrast with the general corrosion , corrosion rate increases with increasing temperature ;

⑶ scale technical ability requirements for calcium, magnesium , iron has a strong complexing ability , particularly Fe3 + has an excellent chelating ;

Steel surface cleaning agent : steel surface plated bowl as needed , chrome , tin , nickel- plated to suit the special purpose , its slab surface shall be rigorously cleaned , the coating material combined with a solid steel surface , this time adding its cleaning agents sodium gluconate will achieve very good results ;

Pipeline ; rust on the bottle labels and bottlenecks to dye force is not ideal ; washed trace residues on food security is not ideal ( such as phosphate residues ) ; wash water discharged into public nuisance ;

2 , the indicator

Content ≥ 98% ≥ 98% ≥ 98.5%

Chloride – ≤ 0.07% ≤ 0.05%

Arsenic ≤ 3P.P.M ≤ 3P.P.M ≤ 3P.P.M

Lead salts ≤ 10P.P.M ≤ 10P.P.M ≤ 0.001%

Heavy metals ≤ 20P.P.M ≤ 20P.P.M ≤ 0.002%

Sulfate – ≤ 0.05% ≤ 0.05%

Restore matter ≤ 0.5% ≤ 0.5% ≤ 0.5%

3 Synthesis

Industry generally substance containing glucose ( e.g., grain ) as raw materials, the first method by fermentation of glucose to obtain gluconic acid and then neutralized by the sodium hydroxide , sodium gluconate can be obtained , electrolysis and oxidation may also be synthesis. Our most used chemical oxidation – hypobromite oxidation to produce synthetic .

The enzyme according to the different types of fermentation , fermentation can be divided into two clocks, one kind of enzyme is Aspergillus Niger , another acid , the glucose dehydrogenase is formed by means of a law of a lactone , and the decomposition of the ester .

Sodium gluconate may be obtained directly from the fermentation of glucose . In this case , the composition of the fermentation substrate can be held as follows: glucose 250 ~ 350g / L, magnesium sulfate heptahydrate 0.2 ~ 0.3g / L, urea, diammonium phosphate , or 0.4 ~ 0.5g / L. This matrix must be sterilized . The fermentation process, the temperature is controlled to 30-32 ° , pH ~ 50% with 30% sodium hydroxide solution is controlled to 5.5 to 6.5 , the fermentation process lasts 40 ~ 100h. Then , filtration and washing by removing microorganisms , active carbon , filtered , concentrated or spray dried to obtain the finished result .

4 , security

Sodium gluconate nontoxic. Sodium gluconate and chelates with metal ions present in the water formed , through ordinary biological treatment rapidly and completely degraded. Released during the degradation of the heavy metal ions can be removed by precipitation or adsorption on the wastewater treatment sludge which is formed during the removal .

Sodium gluconate Application

Sodium gluconate Application

Steel surface cleaning agent used :

If you need plated steel surfaces bowl , chrome , tin , nickel- plated to suit special applications such as the manufacture of tinplate , galvanized plate , chrome plated ( electrical degrees ) , with its slab surface shall be rigorously cleaned , the coating material and steel the surface of a solid combination , this time adding its sodium gluconate cleaning agents will reach very good results. This has been confirmed by a large international company manufacturing tinplate .

Used as a cement admixture :

After a certain amount of glucose added to the cement , sodium can increase the plasticity and strength of the concrete , and there is blocking effect

, Postpone the concrete during the initial and final solidification , such as adding 0.15% of sodium gluconate , can be extended at the beginning of the coagulation time of more than 10 times the concrete , the concrete is moldable time from hours to days to extend , without affecting the its fastness. Plasticity and delaying the initial solidification time is a very important issue in the concrete operations, such as high temperatures and large-scale construction projects seasonal jobs , delaying the initial solidification time is a problem, sodium gluconate can satisfactorily solve this problem. Also glued well at high temperatures is more difficult , added sodium gluconate concrete after high temperature at 170 ℃ , within a few hours of plastic , so these issues can be satisfactorily resolved . Therefore, as a cement admixture of sodium gluconate has been widely used in foreign countries important building projects, such as the Middle East, a lot of bridge engineering . But we have yet to promote the use of domestic applications in this regard , is said to have refined cellulose sodium in papermaking wastewater , the effect of sodium gluconate is simply not comparable .

But can also used in electroplating , film manufacturing industry.

As a multi- hydroxy acid type excellent corrosion inhibitor sodium gluconate , as with many of the above specific properties, such as can be willing to work hard in the application of technology , will be developed into a big industry .

Sodium gluconate is used in the construction industry

Concrete is a combination of materials made of cement , aggregate, admixtures and water. Concrete is made of artificial material for all the most abundant . Three-quarters of concrete aggregate, however, the most active ingredient in concrete grout . The nature and properties of concrete depends mainly on the nature of the grout . Concrete admixtures can provide some beneficial effects , such as accelerated clotting , slow solidification , the air into a bubble-like existence , reduce water consumption and increase the plasticity and so on. Usually use several kinds in the cement admixture , the admixture of the various applications can be enhanced in some other.

Sodium gluconate can be used as an admixture in concrete , it features in concrete as follows : water reducer and retarder

Sodium gluconate is generally used alone , but in combination with other retarders such as carbohydrates and used together with phosphate . Sodium gluconate is a crystalline powder. Is produced under proper conditions and control requirements . This compound is chemically pure and non-corrosive. Quality is constant . These features ensure that a reliable and reproducible results in the application.

As a reducing agent sodium gluconate

By adding a reducing agent, the water to cement ratio (W / C) can be reduced . Sodium gluconate can be obtained by adding the following effects: 1 , enhance the work of the ratio of water to cement (W / C) remain unchanged, adding sodium gluconate can enhance workability . At this time , from the sodium gluconate is a plasticizer . In less than 0.1% of sodium gluconate plus the amount which is proportional to the degree of improvement and the amount of work . 2 , enhancing the strength of the cement when the concrete content is kept constant and the water content can be reduced ( i.e., W / C lower ) . When the amount of sodium gluconate was 0.1 %, the amount of water can be reduced by 10%. 3 , reducing the amount of water and cement with the ratio to reduce the cement content , W / C ratio is kept constant. In this case, the reduction agent is sodium gluconate as a cement . Under normal circumstances, these two aspects of the performance of concrete , said it was important : contraction and generate heat.

Sodium gluconate as a retarder

Sodium gluconate can significantly delay the start time and the end of the solidification of the concrete. In the amount of 0.15 % or less, with the logarithm of the initial solidification increase the amount of time proportional relationship, that with increase the amount to double clotting time delay to the start times , which makes it able to work from the time few hours to a few days without compromising on strength. Especially hot days and a longer time to be placed , this is an important advantage .

Used as a cleaning agent bottles :

Beverage industry, food industry , brewing industry, the number of days to hundreds of millions of dollars in glass bottles, such as soda bottles , beer bottles, milk bottles , cans bottles, soy sauce , wine bottles , etc. , the cleaning work is a very important thing, cleaning pharmaceutical formulations agent is a higher degree of difficulty of the technical work . Currently not yet appeared an ideal drug . The main problems are: detergent is not strong, easy to plug the washing machine nozzle and pipe ; rust on bottle labels and bottlenecks to dye force is not ideal ; washed trace residues on food security is not ideal ( such as phosphate residues ) ; wash water discharge into public nuisance ( can not comply with the national standard ) . Such as sodium gluconate use in pharmaceutical formulations in their glass as the main cleaning agent , the above problems can be solved. ( Eighties bottling has been done in Shanghai , Shanghai brewery large trials have identification to prove ) this application is not yet developed , if a market has great potential .

Water is used as a stabilizer :

Because sodium gluconate has excellent corrosion and scale effect, it is widely used in water stabilizer , such as the petrochemical business cycle cooling water system , low pressure boilers, engine cooling water systems and other treatment agents . Because it has the following specific advantages : ⑴ obvious coordination effects. Suitable molybdenum, silicon, phosphorus , tungsten, nitrite formulations , the coordination Effect , the inhibition effect is greatly improved. ⑵ corrosion rate increases with increasing temperature . General corrosion inhibition efficiency increased with increasing temperature drop , or even completely useless. But contrary sodium gluconate , corrosion rates within a certain range to improve with increasing temperature , for example, carbon steel and other materials test , the temperature rose from 77 ℃ F on to 120 ℃ F, its average rate of 5% buffer above . Therefore, this singular feature of sodium gluconate , the higher the temperature of the system from low to high temperatures or temperature variation system , is ideal to use as a corrosion inhibitor . ⑶ scale capability: calcium , magnesium , iron complex has a strong ability to scale so strong, particularly Fe3 + chelation excellent , even in the full scope of the role of internal PH . ⑷ eliminate pollution. Using sodium gluconate as circulating cooling water corrosion inhibitor , to eliminate pollution , which is an advantage other corrosion inhibitor currently in use can not be compared.

Used in medicine :

Regulation of acid-base balance in the human body to restore nerve function properly , but also for the same purpose , used in food additives

Sulfamic acid

Name : Sulfamic acid

English Name : ACETO ACID; AMIDOSULFONIC ACID; AMIDOSULFURIC ACID; AMINOSULFONIC ACID; BETZ 0254; SULFAMIDIC ACID; SULFAMINIC ACID; SULPHAMIC ACID; aminosulfuricacid; Imidosulfonic acid; Jumbo; Kyselina amidosulfonova; Kyselina sulfaminova; kyselinaamidosulfonova; kyselinaamidosulfonova (czech); kyselinasulfaminova; kyselinasulfaminova (czech); sulfamic; sulphamidic acid

Grade : AR

CAS No. :5329 -14-6 [ 1 ]

Formula : H3NO3S

Weight: 97.09

supplies: http://www.lubonchem.com

No. MDL: MFCD00011603

EC Number: 226-218-8

2 Products

Raw materials : urea, fuming sulfuric acid, chlorosulfonic acid

Preparation Products : cobalt sulfamate , nickel sulfamate , Acid Green 20 , cyclamate, detergents, alkali superplasticizer , affinity of the toner , ammonium sulfamate , strong detergents , cleaning agents

Characters

Colorless or white crystals , soluble in water, slightly soluble in ethanol and methanol, slightly soluble in acetone, ether insoluble in aqueous solution gradually break down into ammonium bisulfate , water solubility :. 146.8 g / l (20 ℃)

Physical parameters

Melting point : 215-225 ℃

Storage and transportation

Sealed dry place.

Instructions for use

Standard amount of the base titration , complexation masking agents , organic trace analysis of nitrogen and sulfur determination criteria .

Hazard statement

Dangerous code : Xi

Hazard Class : R36/38- R52/53

Security Level : S26-S28-S61

3 Synthetic Method

An amino acid produced in many ways, sulfur dioxide or acetone oxime with hydroxylamine as raw material hydroxylamine , sulfite or sulfate and ammonia as raw materials ammoniting , urea and chlorine acid as raw materials sulfochlorination law , fuming sulfuric acid and urea as raw fuming sulfuric acid , urea , sulfur trioxide and sulfuric acid as raw materials and fuming sulfuric acid method (also known as liquid phase ) and ammonia via gasification and sulfur trioxide in Gas under vapor phase reaction conditions and the like. Domestic and industrial significance of the process has to send two amination with ammonia and direct synthesis of sulfur trioxide fuming sulfuric acid method. Urea is sulfonated with fuming sulfuric acid to form an amino acid in the crude 40-70 ℃, and then water was added for crystallization to obtain the amino acid product. Consumption of raw materials fixed: Urea 2000kg / t, oleum 1500kg / t.

2 , there are two main methods synthesis gas and liquid method. Fumed harsh operating conditions , equipment material requirements . Byproducts and more easily adhere to the amino acids and the reactor wall need regular cleaning. High production costs . The advantage is the high product purity. Manufacturers use mostly liquid phase .

3 excess fuming sulfuric acid in the reaction vessel , cooled with stirring to 20 ~ 40 ℃, start adding the mixed proportion of urea and sulfuric acid . After completion of the addition , stirring at about 20 ℃ 8 h. Then gradually warmed to 70 ~ 90 ℃, distilled sulfur trioxide , cooling crystallization . The crude obtained after the solid-liquid share amino acid, and recrystallized from water , dehydrated and dried to obtain a high-purity quality amino acid.

Four amino acid is a strong Lewis acid and a strong Lewis base NH3 SO3 adduct , prepared a small amount of high purity when the amino acid , in a completely anhydrous conditions , with high purity directly by reaction with ammonia SO3 . If a larger amount of urea is available with fuming sulfuric acid reaction to the system. The round bottom flask equipped with a mechanical stirrer was placed in the water bath , to which was added 560g 100% sulfuric acid under vigorous stirring to 100g of urea times ( about 45min plus End ) was slowly added to sulfuric acid , being careful not the temperature exceed 40 ℃. Then thereto was added 309g of fuming sulfuric acid ( containing 65 % free SO3), and 16h is placed at a temperature of 42 ~ 45 ℃ . Filtered through a glass frit funnel the reaction mixture was washed first with pure sulfuric acid , washed with 50% sulfuric acid , washed with cold methanol and finally with .

5 heating oleum 20% to 30 ℃, urea was slowly added , the temperature controlled at 60 ~ 65 ℃, after adding heat 3H, then warmed to 80 ~ 85 ℃, incubated 2h, after the reaction was cooled to 5 ℃, filtration, drying the obtained crystals by centrifugation , washed with 5% ethanol and recrystallized with distilled water and drained after purification to obtain pure amino acid .

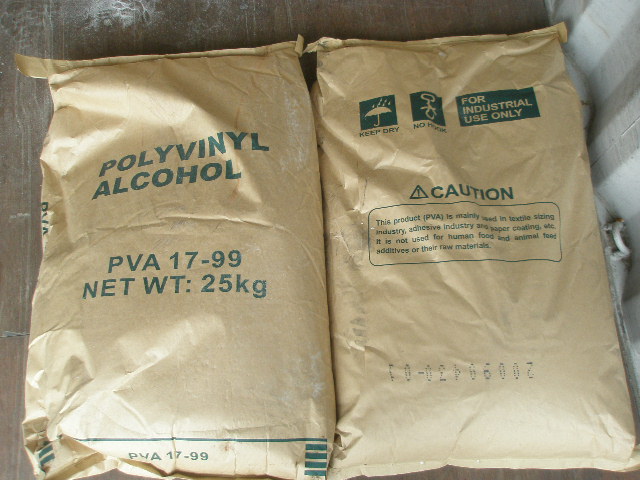

Polyvinyl alcohol

Chemicals Name : polyvinyl alcohol, vinylalcohol polymer, poval, referred to as PVA

CAS No. :9002-89-5

Formula : [C2H4O] n

Molecular weight: 44.05

Structure:Non-toxic

supplies:http://www.lubonchem.com

1,Security terms : S24/25 Avoid contact with skin and eyes Avoid contact with skin and eyes.

S26In case of contact with eyes, rinse immediately with plenty of water and seek medical advice.

In case of contact with eyes, rinse immediately with plenty of water and seek medical advice .

S36/37Wear suitable protective clothing and gloves.

Wear suitable protective clothing and gloves.

S24/25Avoid contact with skin and eyes.

Avoid contact with skin and eyes.

S45In case of accident or if you feel unwell, seek medical advice immediately (show the label whenever possible.)

In case of accident or feel unwell, seek medical advice immediately ( if possible show the label ) .

Risk Phrases R23/24/25Toxic by inhalation, in contact with skin and if swallowed.

Inhalation , in contact with skin and if swallowed poisonous.

2, Technical indicators

Polyvinyl alcohol product standards (cp2010)

No. Index Name Standard

1 Exterior White powder

2 Viscosity 3-70

3 PH value 4.5 ~ 6.5

4 Loss on drying ≤ 5.0

5 Residue on ignition ≤ 0.5

6 Acid value ≤ 3.0%

7 Alcoholysis 85 ~ 89

8 Heavy Metal ≤ 10PPM

Polyvinyl alcohol product standards (USP25)

Low viscosity

No. Index Name Standard

1 Exterior White powder

2 Viscosity 4.0 ~ 7.0

3 PH value 5-8

4 The average molecular weight 16000 to 20000

5 Loss on drying ≤ 5.0

6 Residue on ignition ≤ 2.0

7 Water- insoluble impurities ≤ 0.1%

8 The degree of hydrolysis +

9 Organic volatile impurities +

10 Content 85.0% ~ 115.0%

Medium viscosity

No. Index Name Standard

1 Exterior White powder

2 Viscosity 21.0 ~ 33.0

3 PH value 5-8

4 The average molecular weight 110000 ~ 130000

5 Loss on drying ≤ 5.0

6 Residue on ignition ≤ 2.0

7 Water- insoluble impurities ≤ 0.1%

8 The degree of hydrolysis +

9 Organic volatile impurities +

10 Content 85.0% ~ 115.0%

High viscosity

No. Index Name Standard

1 Exterior White powder

2 Viscosity 40.0 to 65.0

3 PH value 5-8

4 The average molecular weight 180000 to 200000

5 Loss on drying ≤ 5.0

6 Residue on ignition ≤ 2.0

7 Water- insoluble impurities ≤ 0.1%

8 The degree of hydrolysis +

9 Organic volatile impurities +

10 Content 85.0% ~ 115.0%

3, Pharmaceutical Grade

Pharmaceutical grade and specifications with EG , EG system uses. Pharmaceutical grade polyvinyl alcohol , polyvinyl alcohol level is different from the chemical industry , it is a very safe organic polymer , non-toxic to humans , no side effects, biocompatible , water-based gel , especially if he ‘s in medical in ophthalmology , wound dressings and artificial joints aspects are widely used in pharmaceutical polyvinyl alcohol film while the film , an artificial kidney film also has to use. Its security can be used to repair skin wounds , eye drops and eye products visible in general. Some models are also often used in cosmetics mask, cleanser , lotion and emulsion , is a commonly used security into film.

4,Risk

Health hazard : inhalation , ingestion or absorption through the skin harmful to eyes and skin

Stimulation.

Explosion hazard: The product is flammable , irritating.

5,Aid measures

Skin contact: Remove contaminated clothing, mobile water rinse .

Eye contact: Did eyelid, mobile water or saline. Doctor.

Inhalation: from the scene to fresh air. If breathing is difficult , give oxygen. Doctor.

Ingestion : drink plenty of water, induce vomiting . Doctor.

6, Fire-fighting measures

Hazardous characteristics : powder can form explosive mixtures with air , when it reaches a certain concentration, when Mars will explode. The thermal decomposition of flammable gases.

Hazardous combustion products : carbon monoxide, carbon dioxide.

Fire fighting methods : firefighters are required to wear gas masks, body wear firefighting suits , fire in the wind . Extinguishing Media: Water spray, foam, dry powder , carbon dioxide , sand.

7 leak handling

Emergency treatment: isolation leak contaminated areas, restricting access. Cut off the fire source . Recommended emergency personnel wearing a dust mask ( full cover ) , wear protective clothing. To avoid dust, carefully scan, bag placed transfer to a safe place . You can also rinse with plenty of water , wash water diluted into the wastewater system . If large spills, using plastic sheeting, canvas cover . Recycling or collection shipped to the waste disposal sites.

8, Handling

Handling Precautions: provide good natural ventilation.

The operator must go through specialized training , strict adherence to rules . Proposed operators wear self-absorption filter respirators , wearing chemical protective safety glasses , wear protective overalls on infiltration , wear rubber gloves. Away from fire , heat, workplace smoking . Use explosion-proof ventilation systems and equipment. Avoid generating dust . Avoid contact with oxidizing agents . Handling of light when light unloading , packaging and containers to prevent damage . Corresponding with the variety and quantity of fire equipment and emergency equipment leakage . Empty containers may be harmful residues .

Storage: Store in a cool , ventilated warehouse. Keep away from fire and heat. Oxidants should be stored separately and avoid mixing reservoir . Corresponding with the variety and quantity of fire equipment . Storage areas should be equipped with suitable material spill .