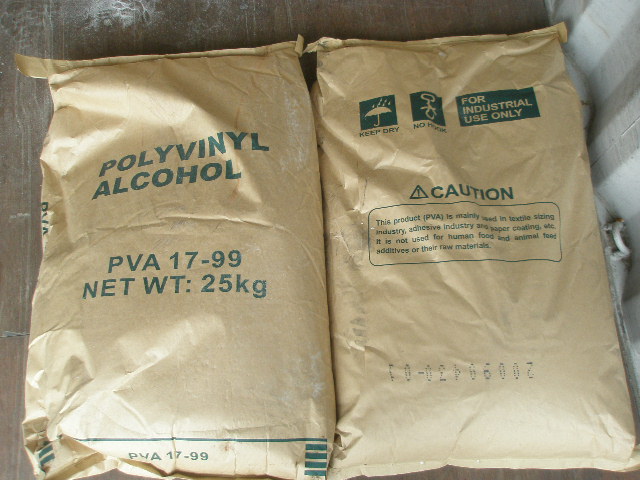

Chemicals Name : polyvinyl alcohol, vinylalcohol polymer, poval, referred to as PVA

CAS No. :9002-89-5

Formula : [C2H4O] n

Molecular weight: 44.05

Structure:Non-toxic

supplies:http://www.lubonchem.com

1,Security terms : S24/25 Avoid contact with skin and eyes Avoid contact with skin and eyes.

S26In case of contact with eyes, rinse immediately with plenty of water and seek medical advice.

In case of contact with eyes, rinse immediately with plenty of water and seek medical advice .

S36/37Wear suitable protective clothing and gloves.

Wear suitable protective clothing and gloves.

S24/25Avoid contact with skin and eyes.

Avoid contact with skin and eyes.

S45In case of accident or if you feel unwell, seek medical advice immediately (show the label whenever possible.)

In case of accident or feel unwell, seek medical advice immediately ( if possible show the label ) .

Risk Phrases R23/24/25Toxic by inhalation, in contact with skin and if swallowed.

Inhalation , in contact with skin and if swallowed poisonous.

2, Technical indicators

Polyvinyl alcohol product standards (cp2010)

No. Index Name Standard

1 Exterior White powder

2 Viscosity 3-70

3 PH value 4.5 ~ 6.5

4 Loss on drying ≤ 5.0

5 Residue on ignition ≤ 0.5

6 Acid value ≤ 3.0%

7 Alcoholysis 85 ~ 89

8 Heavy Metal ≤ 10PPM

Polyvinyl alcohol product standards (USP25)

Low viscosity

No. Index Name Standard

1 Exterior White powder

2 Viscosity 4.0 ~ 7.0

3 PH value 5-8

4 The average molecular weight 16000 to 20000

5 Loss on drying ≤ 5.0

6 Residue on ignition ≤ 2.0

7 Water- insoluble impurities ≤ 0.1%

8 The degree of hydrolysis +

9 Organic volatile impurities +

10 Content 85.0% ~ 115.0%

Medium viscosity

No. Index Name Standard

1 Exterior White powder

2 Viscosity 21.0 ~ 33.0

3 PH value 5-8

4 The average molecular weight 110000 ~ 130000

5 Loss on drying ≤ 5.0

6 Residue on ignition ≤ 2.0

7 Water- insoluble impurities ≤ 0.1%

8 The degree of hydrolysis +

9 Organic volatile impurities +

10 Content 85.0% ~ 115.0%

High viscosity

No. Index Name Standard

1 Exterior White powder

2 Viscosity 40.0 to 65.0

3 PH value 5-8

4 The average molecular weight 180000 to 200000

5 Loss on drying ≤ 5.0

6 Residue on ignition ≤ 2.0

7 Water- insoluble impurities ≤ 0.1%

8 The degree of hydrolysis +

9 Organic volatile impurities +

10 Content 85.0% ~ 115.0%

3, Pharmaceutical Grade

Pharmaceutical grade and specifications with EG , EG system uses. Pharmaceutical grade polyvinyl alcohol , polyvinyl alcohol level is different from the chemical industry , it is a very safe organic polymer , non-toxic to humans , no side effects, biocompatible , water-based gel , especially if he ‘s in medical in ophthalmology , wound dressings and artificial joints aspects are widely used in pharmaceutical polyvinyl alcohol film while the film , an artificial kidney film also has to use. Its security can be used to repair skin wounds , eye drops and eye products visible in general. Some models are also often used in cosmetics mask, cleanser , lotion and emulsion , is a commonly used security into film.

4,Risk

Health hazard : inhalation , ingestion or absorption through the skin harmful to eyes and skin

Stimulation.

Explosion hazard: The product is flammable , irritating.

5,Aid measures

Skin contact: Remove contaminated clothing, mobile water rinse .

Eye contact: Did eyelid, mobile water or saline. Doctor.

Inhalation: from the scene to fresh air. If breathing is difficult , give oxygen. Doctor.

Ingestion : drink plenty of water, induce vomiting . Doctor.

6, Fire-fighting measures

Hazardous characteristics : powder can form explosive mixtures with air , when it reaches a certain concentration, when Mars will explode. The thermal decomposition of flammable gases.

Hazardous combustion products : carbon monoxide, carbon dioxide.

Fire fighting methods : firefighters are required to wear gas masks, body wear firefighting suits , fire in the wind . Extinguishing Media: Water spray, foam, dry powder , carbon dioxide , sand.

7 leak handling

Emergency treatment: isolation leak contaminated areas, restricting access. Cut off the fire source . Recommended emergency personnel wearing a dust mask ( full cover ) , wear protective clothing. To avoid dust, carefully scan, bag placed transfer to a safe place . You can also rinse with plenty of water , wash water diluted into the wastewater system . If large spills, using plastic sheeting, canvas cover . Recycling or collection shipped to the waste disposal sites.

8, Handling

Handling Precautions: provide good natural ventilation.

The operator must go through specialized training , strict adherence to rules . Proposed operators wear self-absorption filter respirators , wearing chemical protective safety glasses , wear protective overalls on infiltration , wear rubber gloves. Away from fire , heat, workplace smoking . Use explosion-proof ventilation systems and equipment. Avoid generating dust . Avoid contact with oxidizing agents . Handling of light when light unloading , packaging and containers to prevent damage . Corresponding with the variety and quantity of fire equipment and emergency equipment leakage . Empty containers may be harmful residues .

Storage: Store in a cool , ventilated warehouse. Keep away from fire and heat. Oxidants should be stored separately and avoid mixing reservoir . Corresponding with the variety and quantity of fire equipment . Storage areas should be equipped with suitable material spill .